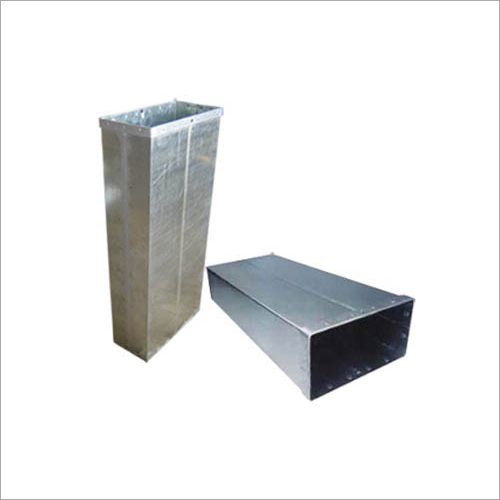

Ammonia Oil Separator

Product Details:

- Usage Industrial

- Product Type Ammonia Oil Separator

- Click to View more

Ammonia Oil Separator Price And Quantity

- 1 Piece

- 500000.00 - 2500000.00 INR/Piece

Ammonia Oil Separator Product Specifications

- Ammonia Oil Separator

- Industrial

Ammonia Oil Separator Trade Information

- 3 Piece Per Month

- 3-4 Week

- All India

Product Description

A tool used in refrigeration systems that employ ammonia as the refrigerant is called an ammonia oil separator. The oil is intended to be returned to the compressor for lubrication after being separated from the ammonia vapour by the device.

In relation to ammonia oil separators, keep in mind the following:

1. The purpose of lubricating the compressor in an ammonia refrigeration system is to ensure smooth operation and guard against damage. However, some oil may combine with the ammonia vapour when the refrigerant passes through the system. To enable recirculation back to the compressor, the oil is taken out of the refrigerant vapour using an ammonia oil separator.

2. The ammonia oil separator uses a mixture of coalescing and gravity separation methods to separate the oil from the ammonia vapour. The oil droplets that were floating in the vapour consolidate into larger droplets, which then gravitationally fall to the bottom of the separator. While the oil-free ammonia vapour travels through the refrigeration system, the separated oil is collected and sent back to the compressor.

3. Design and construction: Cylindrical vessels with interior parts intended to speed up the oil separation process are typical of ammonia oil separators. These devices, such as baffles, mesh pads, or coalescing elements, aid in aggregating the oil droplets and directing their separation. The separator typically has connections for the refrigerant flow's inlet and outlet as well as an oil drain for removing the gathered oil.

4. Sizing and Location: The design of the refrigeration system, the rate of oil circulation, and the system needs all affect the size and capacity of an ammonia oil separator. To guarantee effective oil separation, proper size is essential. The separator is often located upstream of other system parts like heat exchangers or evaporators and downstream of the compressor discharge.

5. Maintenance: To keep the ammonia oil separator running efficiently, routine maintenance is necessary. This include checking the oil level, looking for any oil or refrigerant leaks, and making sure the collected oil is drained properly. To get rid of any impurities or accumulated debris, the separator might also need to be cleaned on occasion.

In order to keep ammonia refrigeration systems lubricated and effective, ammonia oil separators are essential. They support limiting the amount of oil carried over, shield downstream components from oil pollution, and guarantee the system's long-term performance and dependability. For best performance and safety in ammonia refrigeration applications, the ammonia oil separator must be installed, sized, and maintained correctly.