Brine Coil

Product Details:

- Usage Industrial

- Product Type Brine Coil

- Click to View more

Brine Coil Price And Quantity

- 1 Piece

- 500000.00 - 2500000.00 INR/Piece

Brine Coil Product Specifications

- Brine Coil

- Industrial

Brine Coil Trade Information

- 3 Piece Per Month

- Week

- All India

Product Description

In relation to brine coils, remember the following:

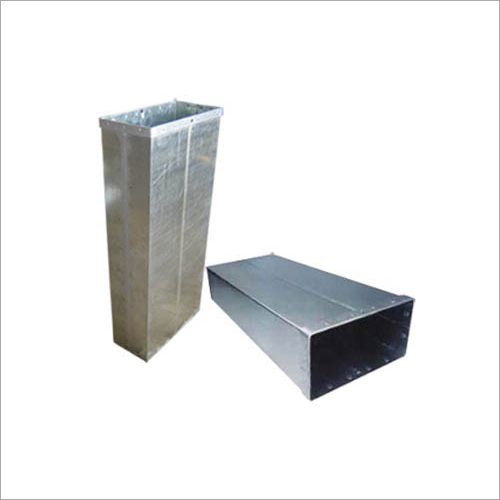

2. Design and Construction: Brine coils are commonly constructed from coils of copper, aluminium, or stainless steel tubing. The corrosiveness of the brine solution and the desired heat transfer efficiency are two parameters that influence the material selection. To increase surface area and promote heat transfer, the coil is frequently enhanced with fins or other features.

3. Brine Solutions: A solution created by combining salt and water is referred to as brine. The application and the preferred temperature range determine the exact content of the brine solution. Calcium chloride, sodium chloride (common table salt), and glycol-based solutions are popular salts used in brine solutions.

4. Applications: Brine coils are used in a variety of systems and industries, such as:

- Brine coils are used in brine chillers or freezers in refrigeration systems to transfer heat from the refrigerant to the brine solution. The brine is employed in the chilling or freezing of goods as well as the cooling of commercial processes.

- Brine coils are used in heat pump systems for applications involving geothermal or water-source heat pumps. They enable effective space heating or cooling by transferring heat from the brine solution to the refrigerant.

- Brine coils are a viable option for thermal energy storage systems that employ chilled brine to store excess or off-peak energy. In the future, during moments of peak demand, the stored energy can be used for cooling.

- Brine coils are employed in a variety of industrial operations where heat transfer is necessary, including chemical processing, the preparation of food and beverages, and the manufacture of pharmaceuticals.

5. Cleaning the coil surface to get rid of any dirt or pollutants that could obstruct heat transfer is a regular part of maintaining brine coils. To guarantee optimum performance and system efficiency, it's also crucial to check for leaks or corrosion.

The needed heat transmission capacity, the make-up of the brine solution, and compatibility with the particular application are all things to take into account when choosing a brine coil. In order to achieve efficient heat transfer and system performance, proper size and installation are essential. A given application's ideal brine coil configuration can be determined with the assistance of industry experts.