Ice Plant Automation

Product Details:

- Usage Industrial

- Product Type Ice Plant Automation

- Click to View more

Ice Plant Automation Price And Quantity

- 1 Piece

- 500000.00 - 2500000.00 INR/Piece

Ice Plant Automation Product Specifications

- Industrial

- Ice Plant Automation

Ice Plant Automation Trade Information

- 3 Piece Per Month

- 3-4 Week

- All India

Product Description

Automation of ice plants primarily refers to the management and optimisation of ice producing activities via the use of technology and automated systems. This may entail different steps in the ice-making process, such as ice manufacture, storage, packaging, and delivery.

The following are some essential ideas of ice plant automation:

1. Automation can be used in the ice-making process to track and manage variables including water temperature, ice thickness, freezing duration, and output capacity. This guarantees ice production's efficiency and high level of quality.

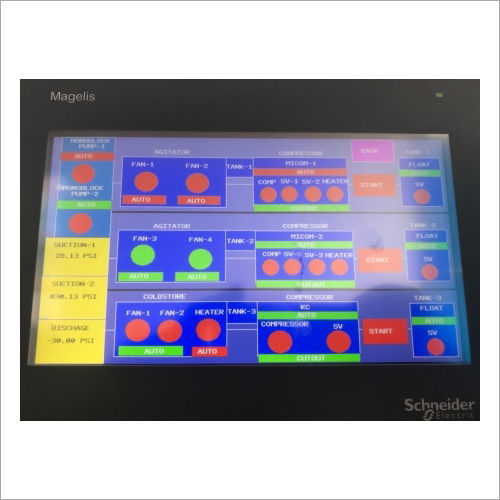

2. Control systems: To regulate the various stages of ice manufacturing, automated control systems, such as programmable logic controllers (PLCs) or computer-based systems, can be used. These systems have the ability to control settings, monitor sensors, and supply real-time data for analysis and improvement.

3. Remote Monitoring and Control: The automation of ice plant operations enables remote monitoring and control. Plant managers or operators can access and administer the system from any location with the use of internet connectivity and the necessary software, enabling remote troubleshooting, data analysis, and operational modifications.

4. Automation systems may have quality control features like sensors or cameras that may identify and discard ice cubes that don't adhere to set criteria. This promotes consistency in quality and lessens the possibility of distributing subpar ice.

5. Inventory Management: Automated systems can analyse usage trends, check ice inventory levels, and send notifications for replenishment. As a result, shortages or overstocking are avoided and the supply chain is made efficient.

6. Energy Efficiency: By monitoring energy use, scheduling production for off-peak times, and installing energy-saving measures like variable speed compressors or effective refrigeration systems, automation can optimise energy utilisation in ice plant operations.

7. Automation systems gather and analyse data from numerous sensors and processes, which is then reported. This information can be utilised to create reports, spot trends, and come to wise judgements about process optimisation, maintenance scheduling, and general improvement.

An ice plant that uses automation can increase production, save costs, produce better products, and manage resources more effectively. However, depending on the size of the ice factory and the desired results, the degree of automation and particular technologies can change. For effective ice plant automation implementation, consulting with professionals in industrial automation and refrigeration systems can offer insightful advice.