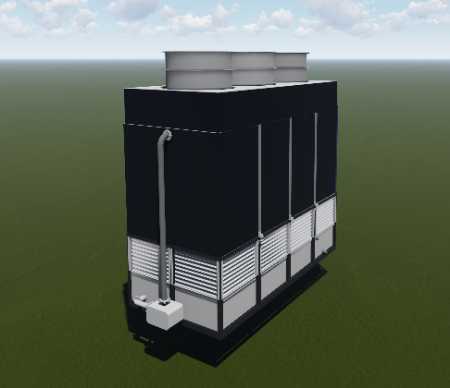

Atmosphreic Condensors

Product Details:

- Usage Industrial

- Product Type Atmosphreic Condensors

- Click to View more

Atmosphreic Condensors Price And Quantity

- 1 Piece

- 500000.00 - 2500000.00 INR/Piece

Atmosphreic Condensors Product Specifications

- Industrial

- Atmosphreic Condensors

Atmosphreic Condensors Trade Information

- 3 Piece Per Month

- 3-4 Week

- All India

Product Description

With no additional water or cooling media required, atmospheric condensers, sometimes referred to as air-cooled condensers, are heat exchangers used in a variety of industries to condense and cool process vapours or fluids. The cooling medium for these condensers is ambient air.

The following are some important aspects of atmospheric condensers:

1. Using the principle of heat transmission from a heated vapour or fluid to the surrounding air, atmospheric condensers function. While ambient air passes over the exterior of the condenser tubes or coils, the vapour or fluid is flowing through them. The hot vapour or fluid dissipates heat and condenses into a liquid form as it interacts with the cooler air.

2. Applications: Atmospheric condensers are used in a variety of processes and industries, such as:

- Petrochemical and Refining: In the petrochemical and refining industries, they are frequently used to condense and cool vapours from distillation columns, fractionators, or other process units.

- Chemical Processing: Process gases or vapours produced during chemical reactions or separation operations are cooled and condensed using atmospheric condensers.

- Power Generation: In power plants, they can be utilised to condense steam from the steam turbine exhaust, turning it back into liquid water for recycling or disposal.

- HVAC and refrigeration systems both use air-cooled condensers, which function as essential parts to cool and condense refrigerant vapours.

- Environmental Control: Volatile organic compounds (VOCs) or other contaminants can be recovered from process exhaust gases using atmospheric condensers in environmental control systems.

3. Design and Construction: To provide a large surface area for heat transmission, atmospheric condensers are often built using a series of tubes or coils. Materials like copper, aluminium, or stainless steel are possible choices for the tubes or coils' construction. To increase the surface area and boost the effectiveness of heat transfer, the design may contain fins or other improvements.

4. Fan Systems: Atmospheric condensers use blowers or fans to help the air pass over the coils or tubes of the condenser. These fans contribute to a consistent airflow and improve cooling.

5. Atmospheric condensers provide a number of benefits:

- Water Conservation: By removing the requirement for water as a cooling medium, they save this precious resource and use less of it.

- Simpler Design: Compared to water-cooled condensers, atmospheric condensers have a simpler design that makes them easier to install and operate. This is because they do not need a water supply or cooling towers.

- Savings: Atmospheric condensers can reduce operating costs by removing the requirement for water and the associated costs of water treatment and maintenance.

When choosing an atmospheric condenser, it's vital to take into account variables including heat load, ambient temperatures, space availability, and the particular needs of the application. For optimum performance and efficiency, working with skilled engineers or consultants can help assure proper sizing, design, and installation.