Cooling Tower

Product Details:

- Usage Industrial

- Product Type Cooling Tower

- Click to View more

Cooling Tower Price And Quantity

- 500000.00 - 2500000.00 INR/Piece

- 1 Piece

Cooling Tower Product Specifications

- Industrial

- Cooling Tower

Cooling Tower Trade Information

- 3 Piece Per Month

- 3-4 Week

- All India

Product Description

A cooling tower is a device that transfers extra heat from HVAC systems or industrial activities to the atmosphere. This is accomplished by means of convection and evaporation. Power plants, refineries, chemical plants, major building HVAC systems, and other industrial facilities frequently contain cooling towers.

Following are some crucial details about cooling towers:

1. In order to remove heat from water or other process fluids, cooling towers primarily evaporate a small amount of the water. The cooling tower is filled with hot water or another process fluid, which is then spread across packing or fill media. A portion of the water evaporates as air is pushed through the tower by fans, removing heat and cooling the remaining water. After cooling, the water is recirculated for use in the machinery or process.

2. Different types of cooling towers exist, including the following:

- Mechanical Draught Cooling Towers: The air is pushed through these cooling towers by mechanical fans. They can also be divided into forced draught (fans at the bottom of the tower) and induced draught (fans at the top of the tower). Mechanical draught cooling towers can be more effective and provide better control over air flow rates.

- Natural Draught Cooling Towers: In order to create airflow, natural draught cooling towers rely on the buoyancy of warm air. Instead of using mechanical fans, they have a tall structure that resembles a chimney and creates a draught as heated air rises. Large-scale power stations frequently employ cooling towers with natural draughts.

- Combined features of mechanical and natural draught cooling towers are seen in hybrid cooling towers. They use fans to help with airflow and also make use of the buoyancy effect. A balance between effectiveness and affordability is provided by hybrid towers.

- Fill Media or Packing: This is the substance used inside the tower to expand the area where the air and water come into contact, promoting heat transmission.

- Drift Eliminators: These tools reduce the amount of water droplets that are expelled with the exhaust air from the cooling tower. They lessen both the chance of environmental pollution and water loss.

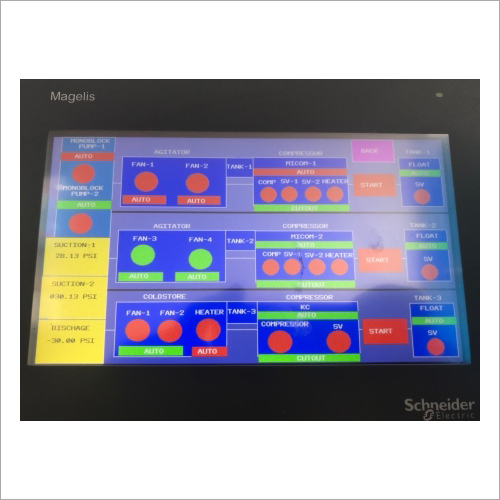

- Airflow through cooling towers is created by fans, which improves the process of evaporation and heat transmission.

- Water Distribution System: The water distribution system makes sure that water is distributed evenly over the fill media, maximising water-air interaction.

- Water Collection Basin: This gathers cooled water that has been forced through the fill media and sends it back to the machinery or process.

Regular maintenance is necessary to guarantee the efficient and proper operation of cooling towers. This include cleaning the fill medium, testing and maintaining the fans, looking for leaks, keeping an eye on the water quality, and avoiding the buildup of scale or biofouling.

In order to effectively manage the heat produced by industrial operations and HVAC systems, cooling towers are essential. They reduce the need for excessive water usage, aid in preventing equipment overheating, increase energy efficiency, and support environmental sustainability. The right cooling tower type, size, and configuration must be chosen based on the application's specific requirements as well as considerations including heat load, water quality, space availability, and cooling tower configuration.